Alaabta

Shaqada granulation Full iyo waxtarka wax soo saarka sare

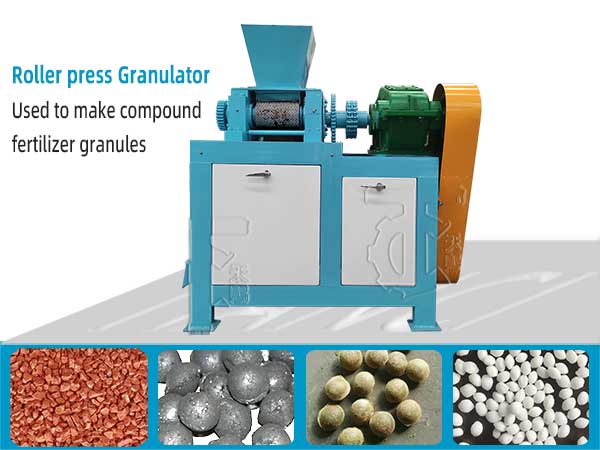

Bacriminta Roller Press Granulator

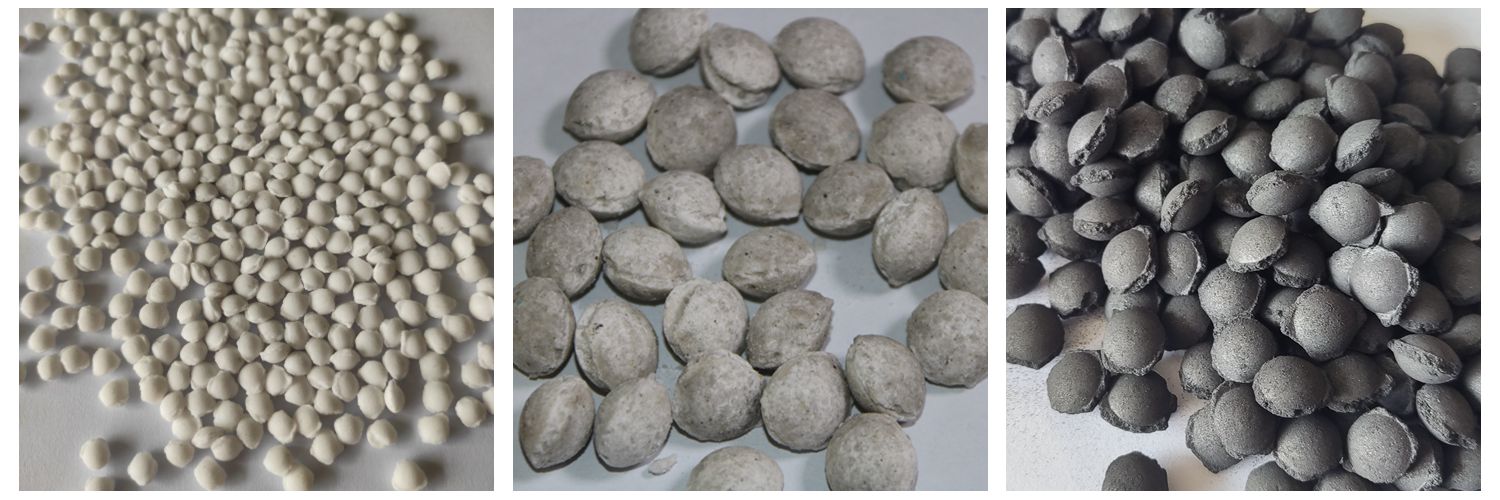

Sharaxaada Alaabta

Granulator press Roller waxaa soo saaray hab aan qallajin, granulating heerkulka qolka, iyo samaynta hal mar. Waxay leedahay sifooyinka maalgashiga yar, saameyn degdeg ah iyo faa'iidooyinka dhaqaale ee wanaagsan. Qaab dhismeedka mashiinkani wuxuu qaataa granulation, samaynta iyo baaritaanka guud ahaan, taas oo ka dhigaysa sifooyinka muuqaalka quruxda badan, hawlgalka fudud iyo isticmaalka tamarta hooseeya.

Mashiinku wuxuu leeyahay la qabsi ballaaran oo alaabta ceeriin ah, kaliya looma isticmaali karo granulation ee bacriminta, quudinta iyo warshadaha kiimikada, laakiin sidoo kale waxay leedahay dabaqo wanaagsan gaar ahaan dhulka naadir ah, birta, dhuxusha, diyaarinta noolaha, iyo mashaariicda ilaalinta deegaanka.

Tilmaamaha Waxqabadka

1. Wareejinta tamarta kinetic waxa la kordhiyaa suunka saddexagalka shan boos, kaas oo si buuxda u wareejinaya awooda matoorka oo yareeya luminta tamarta kinetic.

2.Dib-u-dhiyehu wuxuu qaataa cilmi-baaris madax-bannaan iyo naqshadeynta horumarinta shirkadeena, oo leh waxtarka gudbinta sare iyo tamarta kinetic ee deggan.

3. Nakhshad habka quudinta iyo kicinta si aad u hubiso in maaddadu ay geli karto rullaluistu si siman u dhintaan kana ilaaliso in afka quudinta uu xannibo.

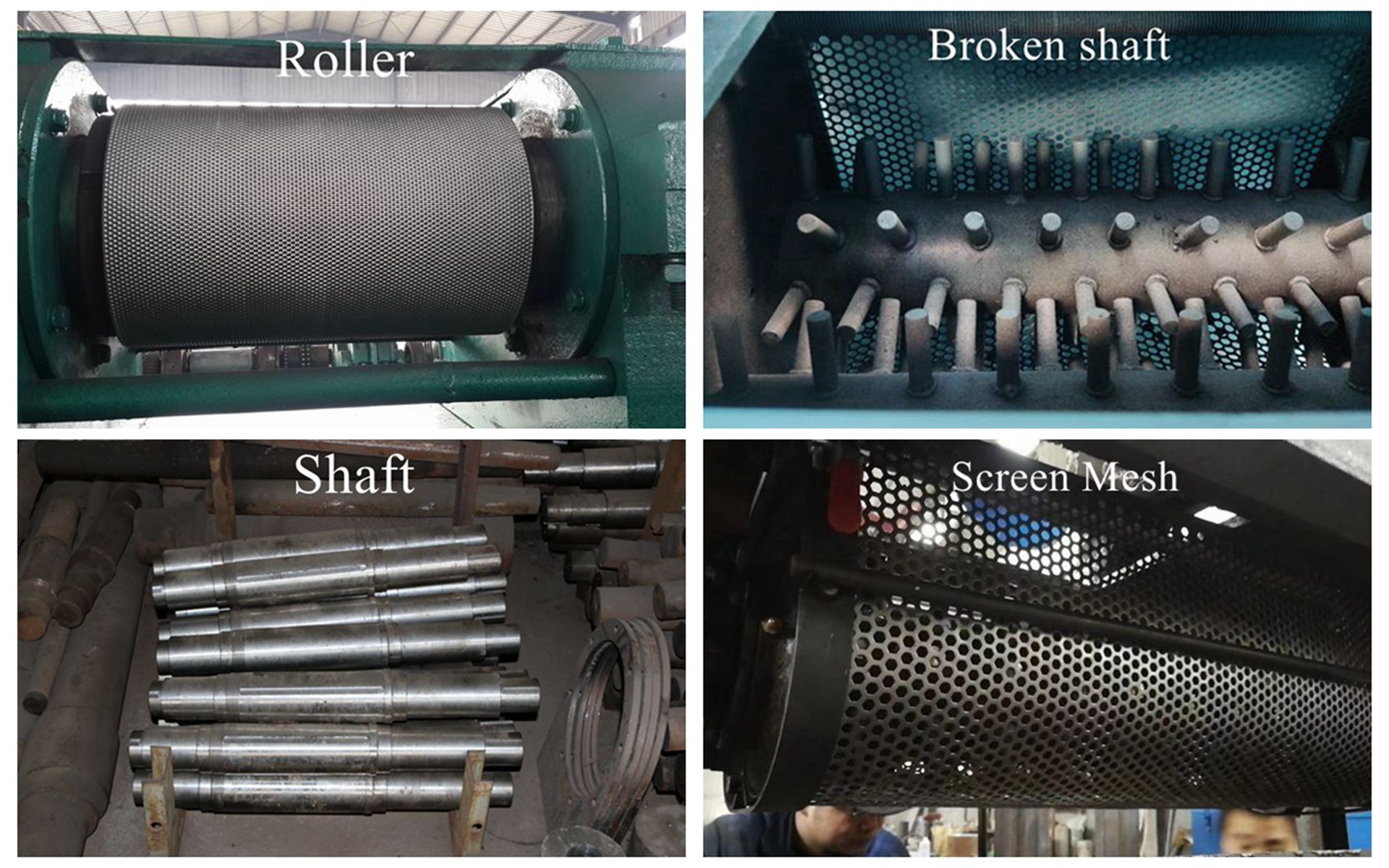

4.Labada dhinac ee dhamaadka hoose ee caaryada maqaarka rullaluistu waxay ku qalabaysan yihiin xoqo nadiifinta si toos ah si looga hortago in alaabta ku dheggan maqaarka rullaluistemadka.

Mabda'a Shaqada

Tani taxane ah granulation rullaluistemadka iska leh model simbiriirixan extrusion, kuwaas oo mabda'a shaqadu waa: suunka iyo jiidi suunka waxaa kaxeeya matoor koronto, oo lagu kala qaado in ay usheeda dhexe drive by reducer, oo ka shaqeeyaan jihada la mid ah iyada oo marsho furan iyo dadban. shaft.Waxyaabaha waxaa lagu daraa hopper quudinta, extruded by rullaluistemadka, hoos u dhigi iyo pelleted, oo dhex maray labo ka mid ah silsiladaha in istuudiyaha shaashadda burburin, halkaas oo alaabta dhammeeyey ee pellets. (kubadaha) waa la baari karaa oo la kala saaraa, ka dibna alaabta dib ayaa loo soo celiyaa oo lagu qasi karaa qalab cusub oo loogu talagalay granulation. Iyadoo wareegga joogtada ah ee mashiinka iyo gelitaanka joogtada ah ee alaabta, wax soo saarka ballaaran ayaa la xaqiijin karaa.

Halbeegyada Farsamo ee ugu muhiimsan

| Qaabka | DJ-Ⅰ-1.0 | DJ-Ⅰ-2.0 | DJ-Ⅰ-3.0 | DJ-Ⅰ-4.0 | DJ-II-1.0 | DJ-II-2.0 | DJ-II-3.0 |

| Awoodda wax-soo-saarka (t/h) | 1-1.5 | 1.5-2.5 | 2.5-3.5 | 3.5-4.5 | 1-2 | 1.5-2.5 | 2.5-3.5 |

| Awood | 15kw | 18.5kw | 22kw | 45kw | 15kw | 18.5kw | 22kw |

| Cabbirka rullaluistemadka cadaadiska | Φ150×220 | Φ150×300 | Φ186×300 | Φ300×300 | Φ150×220 | Φ150×300 | Φ186×300 |

| Cabbirka quudinta | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm |

| Alaabta dhammaatay tilmaamo | Φ2.5-φ10 | Φ2.5-φ10 | Φ2.5-φ20 | Φ2.5-φ30 | Φ2.5-φ10 | Φ2.5-φ20 | Φ2.5-φ20 |

| Nooca yareeya | ZQH350 | ZQH400 | ZQH400 | ZQH500 | ujeedo gaar ah | ujeedo gaar ah | ujeedo gaar ah |

Muuqalka Shaqeynaya

Mashruuca Shaqada

1-20tph warshad bacrimin ah oo leh granulator-jaraa'id:

gaarsiin

Xirmada: xirmo alwaax ah ama weel 20GP/40HQ buuxa ah

Codso Xigasho

Dooro nooca oo meel dalbo

Dooro qaabka oo soo gudbi ulajeedka iibsiga

Hel qiimaha saldhiga

Wax-soo-saarayaashu waxay qaadaan hindisaha inay la xiriiraan oo ay ku wargeliyaan lo

Kormeerka dhirta

Hagaha tababarka khabiirka, soo noqoshada joogtada ah

Saxiix heshiiska

Dooro qaabka oo soo gudbi ulajeedka iibsiga

Ku hel deeqda ugu yar ee bilaashka ah , fadlan ku buuxi macluumaadka soo socda si aad noogu sheegto ( macluumaadka sirta ah , ee aan u furan dadweynaha

Haddii aad xiisaynayso alaabtayada ama aad u baahan tahay inaad wax badan ka ogaato, fadlan guji badhanka la-tashiga ee dhanka midig

Hel xigasho

Hel xigasho +8618937171932

+8618937171932