Alaabta

Shaqada granulation Full iyo waxtarka wax soo saarka sare

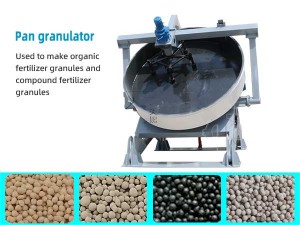

Bacriminta Disc Granulating Machine

Sharaxaada Alaabta

Taxanaha granulator disc waa nooc cusub oo ah granulator disc u janjeera, oo ku habboon in lagu farsameeyo walxaha budada ah ee loo yaqaan granules nooca kubbadda, oo si ballaaran loogu isticmaalo dhirta bacriminta organic, dhirta bacriminta isku dhafan, dhirta daaweynta qashinka wasakhda iyo macdanta, warshadaha kiimikada, quudinta iyo warshadaha kale.

Codsiyada iyo Tilmaamaha

1. Heerka samaynta kubbadda sare,heerka samaynta wuxuu gaari karaa in ka badan 93%.

2. Nolosha dheer ee adeega qalabka. Yareeyaha iyo matoorka waxaa wata suunyo dabacsan, kuwaas oo si habsami leh u bilaabi kara, hoos u dhigi kara saameynta, iyo hagaajinta nolosha adeegga qalabka.

3. Hawl adag oo waara, xasiloon. Qeybta hoose ee looxa granulator-ka waxaa lagu xoojiyay taargooyin bir ah oo kuleyl ah oo badan, waligood ma qallafsan yihiin, dhumucdooduna way culus yihiin, oo leh naqshad sal adag oo aan u baahnayn boolal-barroosin.

4. Nolosha adeeggu waa labanlaab. Saxanka dusha sare ee granulation waxaa lagu dhejiyay balaastiig xoog badan oo muraayad ah oo la xoojiyay, taas oo ah ka hortagga daxalka oo waara.

Halbeegyada Farsamo ee ugu muhiimsan

| Qaabka | Dhexroorka gudaha (mm) | Dhererka dhinaca (mm) | Mugga (m³) | Wareegid xawaaraha (r/min) | Awoodda matoorka (KW) | Awood (t/h) | Wax yareeya model |

| ZL10 | 1000 | 250 | 0.4 | 24 | 2.2 | 0.3-0.5 | XW5-59 |

| ZL15 | 1500 | 300 | 1.1 | 22 | 5.5 | 0.5-0.8 | ZQ250-48 |

| ZL18 | 1800 | 300 | 1.4 | 18 | 5.5 | 0.6-1.0 | ZQ250-48 |

| ZL20 | 2000 | 350 | 1.8 | 18 | 7.5 | 0.8-1.2 | ZQ250-48 |

| ZL25 | 2500 | 350 | 2.5 | 18 | 7.5 | 1.0-1.5 | ZQ400-23 |

| ZL28 | 2800 | 400 | 3.3 | 18 | 11 | 1.0-2.5 | ZQ400-48 |

| ZL30 | 3000 | 450 | 3.9 | 16 | 11 | 2.0-3.0 | ZQ350-23 |

| ZL32 | 3200 | 500 | 4.3 | 13.6 | 15 | 2.0-3.5 | ZQ350-23 |

| ZL36 | 3600 | 550 | 5.5 | 11.3 | 18.5 | 3.0-5.0 | ZQ400-23 |

| ZL45 | 4500 | 600 | 6.5 | 8 | 22 | 4.0-6.0 | ZQ250-48 |

Muuqalka Shaqeynaya

Mashruuca Shaqada

gaarsiin

Xirmada: xirmo alwaax ah ama weel 20GP/40HQ buuxa ah

Codso Xigasho

Dooro nooca oo meel dalbo

Dooro qaabka oo soo gudbi ulajeedka iibsiga

Hel qiimaha saldhiga

Wax-soo-saarayaashu waxay qaadaan hindisaha inay la xiriiraan oo ay ku wargeliyaan lo

Kormeerka dhirta

Hagaha tababarka khabiirka, soo noqoshada joogtada ah

Saxiix heshiiska

Dooro qaabka oo soo gudbi ulajeedka iibsiga

Ku hel deeqda ugu yar ee bilaashka ah , fadlan ku buuxi macluumaadka soo socda si aad noogu sheegto ( macluumaadka sirta ah , ee aan u furan dadweynaha

Haddii aad xiisaynayso alaabtayada ama aad u baahan tahay inaad wax badan ka ogaato, fadlan guji badhanka la-tashiga ee dhanka midig

Hel xigasho

Hel xigasho +8618937171932

+8618937171932